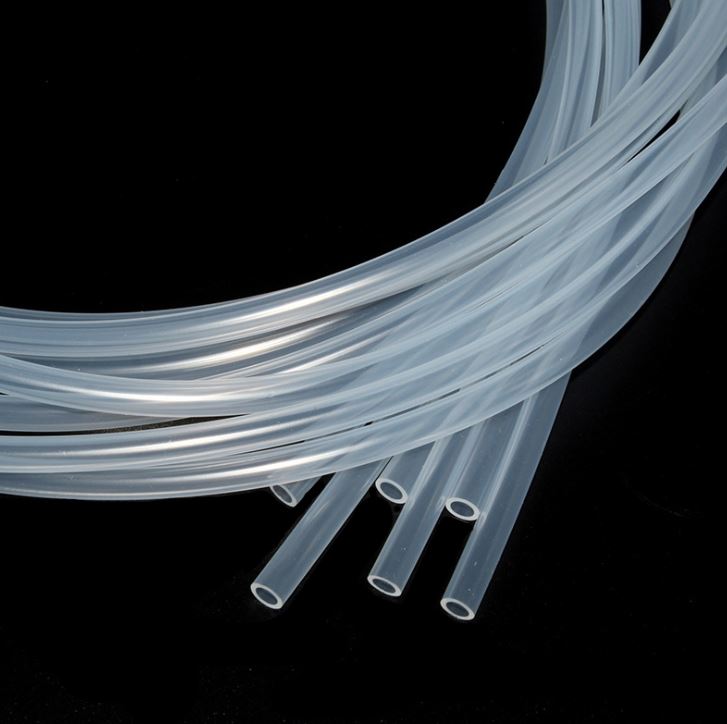

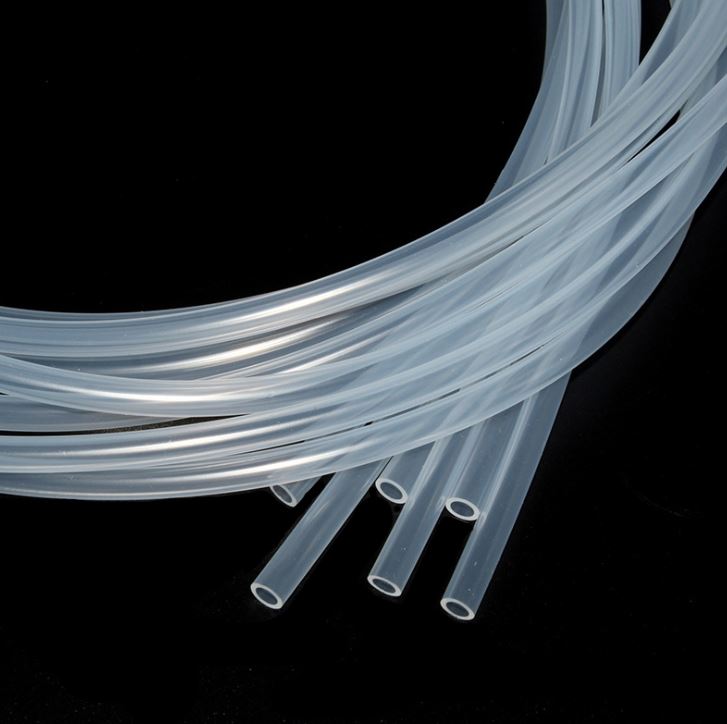

Silicone extrusion process: Silicone rubber is generally soft, has good extrusion effect, and is easy to operate. It can extrude products of various shapes and sizes. Its processing equipment and tools are basically similar to ordinary rubber. The machine usually uses a single-thread screw with Φ30 or Φ65mm, and the length-to-diameter ratio is (10 ~ 12): 1. Keep the temperature as low as possible when extruding, it is better not to exceed 40 ℃, so the barrel and screw must pass cooling water. For products with higher quality requirements, 80-140 mesh filters can be installed near the head to remove impurities in the rubber compound and improve extrusion quality. Silicone rubber extrusion semi-finished products are soft and easily deformed, so they must be vulcanized immediately. The most common method is continuous vulcanization with hot air; the wire and cable industry usually uses high-pressure steam for continuous vulcanization. If continuous vulcanization cannot be performed after extrusion, in order to prevent deformation, it should be picked up with a disc, a drum or a conveyor belt immediately after extrusion, and separated with talc to prevent mutual adhesion. If the rubber compound is found to be too soft to be extruded, 3 to 5 parts of gas phase silica can be mixed into the rubber compound. For rubber compounds used for extrusion, the amount of vulcanizing agent should be appropriately larger than that of molded products. The extrusion speed of silicone rubber is lower than other rubbers. When the same extrusion speed as other rubbers is required, a higher Screw speed

Mobile site

Mobile site WeChat

WeChat